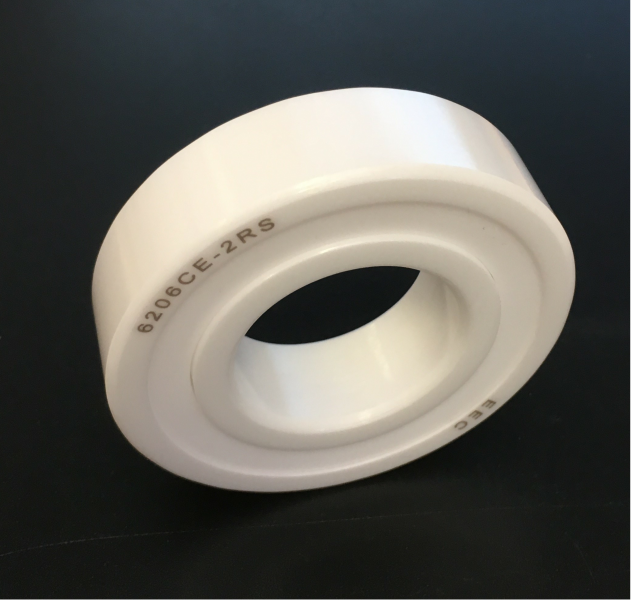

EEC CERAMIC BEARINGS

R&M Bearings specialise in the supply of Ceramic Bearings. Ceramic bearings have excellent performance with their special electrical and magnetism resistance, wear and corrosion resistance, maintenance free lubrication, high and low temperature resistance etc. So they are suitable to be used in tough environments and special conditions.

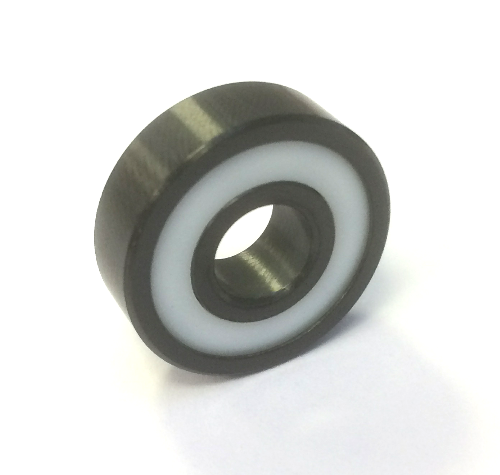

Full ceramic bearings, not to be confused with hybrid ceramic bearings, have many advantages but given their high cost it’s very important to be sure that they will suit your specific application. To help you choose the right bearing, we explain what full ceramic bearings can and can’t do and give some tips on how to choose the right ceramic material.

Our full ceramic ball bearings can be supplied with rings and balls made from zirconia (ZrO2) or silicone nitride (Si3N4). They are available as full complement (no cage) or with a cage made from PEEK or PTFE. Full ceramic bearings are for medium load and medium speed applications. It is not possible to achieve the inner and outer ring roundness that is found with precision steel bearings so full ceramic bearings have lower speed ratings.

They also have lower load ratings than steel bearings. Ceramic materials are much harder than steel but this also means they are more brittle, particularly silicon nitride. This reduces their load ratings.

One benefit of full ceramic bearings is that they are highly corrosion resistant to seawater and most chemicals, including acids and alkalis. They are found in the chemical industry, food and beverage industry, marine applications, chlorine systems, film processing equipment and fuel handling equipment to name just a few areas of use. Full ceramic bearings have excellent low temperature performance which is why they can be found in cryogenic applications. They can also withstand extremely high temperatures so they are often used in furnace applications. As they are non-magnetic, they are suitable for motors used in MRI scanners, magnetometers, semi-conductor manufacturing equipment or any application in which the bearings may be exposed to a strong magnetic field. These bearings are also non-conductive.